Achates Power gets $5 million to build a multi-cylinder version of its diesel engine.

The Jumo engine, made by the German aircraft company Junkers in the 1930s, was an oil-burning, smoke-spewing machine. But it was the most efficient engine of its day. Achates Power, based in San Diego, California, is modifying the design to make it meet modern emissions standards, while improving its efficiency. Data from Achates’s small, single-cylinder test engine convinced the U.S. Army to give Achates, and partner AVL Powertrain Engineering, $4.9 million to build a complete multi-cylinder prototype engine that the Army hopes can be the basis for a range of applications, including powering tanks.

Little engine: Achates has demonstrated the core parts of its technology in this single-cylinder, two-piston engine.

Little engine: Achates has demonstrated the core parts of its technology in this single-cylinder, two-piston engine.

The Army picked Achates because of the potential of its engine to be smaller and more fuel efficient than its conventional engines, while being able to burn a range of different fuels, including jet fuel and diesel. Achates says that its engine, which could also be used in passenger vehicles, could improve the fuel efficiency of a diesel engine by 20 percent.

Since diesel engines are already very efficient, this improvement would result in an engine that’s 50 percent more efficient than gasoline-powered ones, says CEO David Johnson (see “Engine Could Boost Fuel Economy by Half, ” “Exploding Engine Could Reduce Fuel Consumption, ” and “Engine Reinvention”). And he says the engine could cost 10 percent less than a diesel engine, narrowing the gap between diesel and gasoline engines (diesel engines can increase the price of a car by $1, 000 or more).

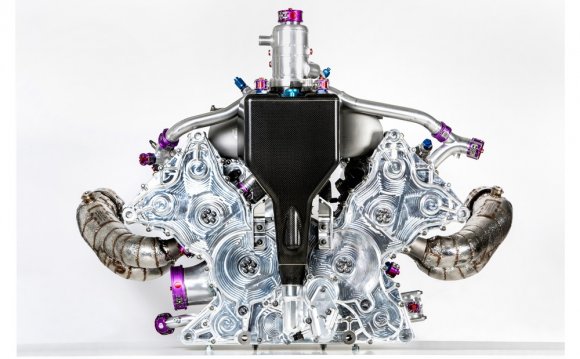

The basic Junkers design has an unusual arrangement of pistons. In a conventional engine, a piston moves inside a cylinder, compressing fuel and air against a cylinder head. A significant amount of energy in fuel ends up heating the cylinder head rather than driving a piston. The Junkers design puts two pistons in the same cylinder and eliminates the cylinder head. Instead, the two pistons compress fuel and air between them and then fly in opposite directions when the fuel is combusted.

To improve emissions and reduce fuel consumption, Achates has made dozens of changes to the original design, including altering the shape of the combustion chamber and improving fuel injection. But so far, its fuel-efficiency claims are based on data from a single-cylinder engine, extrapolated using computer simulations to estimate the performance of a multi-cylinder engine. (Multiple cylinders would be needed for most applications.) The design also hasn’t been tested under all the conditions the engine would see in ordinary driving, such as transitioning from acceleration to cruising or decelerating.

Johnson contends the differences between single-cylinder and multi-cylinder engines are well known and can be accurately modeled.

RELATED VIDEO