5 Fuel-Saving Technologies

5 Fuel-Saving Technologies

In the long run, the internal combustion engine (ICE) is on the way out and electric motors are on the way in, but ICEs have been around for so loooong that we should be careful about announcing their demise. They're going to stick around a while longer, and so it's very important to make them as efficient and clean as possible.

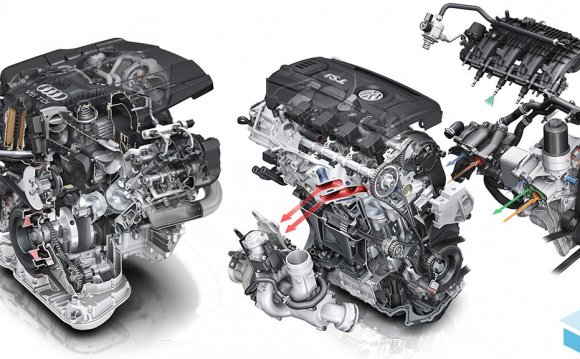

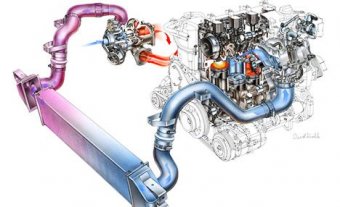

Car and Driver looks at 5 fuel-saving technologies that are keeping the ICE relevant (if far from ideal). As they say, they still work on basically the same principle as they ever did, but old 4-cylinder engines produced about 20 horsepower while modern ones can generate up to 250 hp while being cleaner and burning less gas. Read on for more details on the 5 fuel-saving technologies: Clean diesel, direct injection, cylinder deactivation, turbochargers, and variable valve timing and lift.Clean Diesel

Various advances such as the availability of ultra low sulfur diesel fuel, better catalysts and particulate matter traps, better control over combustion are making diesel engines cleaner, so you can expect a new wave of diesel passenger vehicles to come to the US in the next few years.

Diesel engines are certainly far from perfect, but they have inherently better thermal efficiency than gasoline engines, and they are usually more durable (if also more expensive and heavier). Another benefit is that they can run on biodiesel, which if you can find fuel made from waste cooking oil or (in the next few years) from algae can be very green.

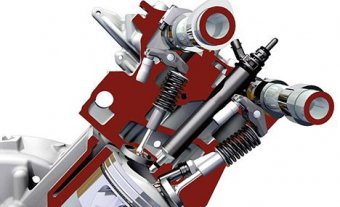

Direct Injection

Before direct injection, the fuel was mixed with air in the car's intake manifold. Now, with direct injection, the fuel is mixed with air inside the cylinder, allowing for better control over the amount of fuel used, and variations depending on demand (acceleration vs. cruising). This makes the engine more fuel efficient.

RELATED VIDEO