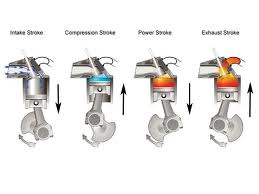

Four-stroke engine diagram

Four-stroke engine diagram

Intake Stroke.

This is the very first step in the chain of events that makes an engine run. This is also the most important step. In this step, mixed air and fuel entering the cylinder through the intake manifold. Incorrectly metered fuel entering the combustion chamber (cylinder) can severly hamper perfromance. Valve clearance is also a very important factor.

During the Intake Stroke, the piston is traveling downwards toward BDC (Bottom Dead Center). At the very same time, the intake lobe on the cam shaft is pushing up on the valve tappet (valve lifter) which opens the intake valve. So at the very moment, the piston is traveling downward while the intake valve is opening. Now the piston is creating negative air pressure or vacuum. Naturally, we can't have negative air pressure, so a charge of gas and air comes rushing into the cylinder through the intake manifold. By the time the piston arrives at BDC, the air pressure inside the cylinder is equal to the air pressure outside the engine. Now, the piston is leaving the BDC position and the cam lobe is leaving the tappet, allowing the valve to close for the next step.

Compression Stroke.

The piston is now traveling back up the cylinder and the intake valve is closing. By the time the piston reaches TDC (Top Dead Center), it has squeezed, lets say, thirteen cubic inches of charge into less than one, it called compression ratio. If your rings and cylinder was is bad shape, most of that charge would have leaked around the rings, reducing the compression ratio.

How healthy your engine is how well the compression stroke works. For the engine to be very efficient, all of the air and fuel mixture must stay inside cylinder as long as possible. And for this to be possible, the compression rings, valves and cylinder must be in good shape to prevent the air and fuel mixture from leaking out.

Power Stroke (Combustion Stroke).

Power Stroke (Combustion Stroke).

The Power Stroke is the most extreme stroke. It puts a great amount of pressure on the entire engine (rings, rod, crankshaft, valves and valve seats and piston.) While the piston was traveling towards TDC, ignition system was building up a charge and at around 12 degrees or less BTDC (Before Top Dead Center), the charge is released and arcs across the spark plug. By the time the piston arrives at TDC, the charge is violently exploded inside the engine, pushing the piston downward.

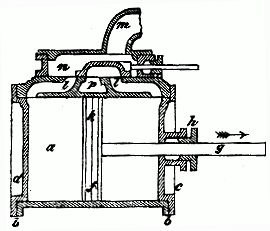

Flywheel

Exhaust Stroke.Now that we had the power stroke and after that we need to get rid of it and start over. With the energy from power stroke, the piston reaches BDC and expained above and begins to travel upwards. While the piston is traveling upwards, the exhaust lobe on the cam gear comes in contact with the exahust tappet (valve lifter), opening the exhaust valve. The exhaust is pushed out of the cylinder as the piston travels upward. By the time the piston reaches TDC, the exhaust valve closes and intake valve opens again, and the cycle is started over.

Now with that said, you may wonder, "If there is only one power stroke for every 4 total strokes, then what makes the engine continue going without stopping, because I know that there is not enough energy created to run the engine for three more strokes before making another power stroke?"

What helps the engine continue through the other three stroke? Strokes inertia. And that inertia can be found in the flywheel. That extra 15 pounds of weight on the crankshaft "pushes" the engine through the other three strokes.

RELATED VIDEO

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving...

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving...

An aircraft engine is the component of the propulsion system for an aircraft that generates mechanical power. Aircraft engines are almost always either lightweight piston engines or gas turbines. This article is an overview of the basic types of aircraft engines and...

An aircraft engine is the component of the propulsion system for an aircraft that generates mechanical power. Aircraft engines are almost always either lightweight piston engines or gas turbines. This article is an overview of the basic types of aircraft engines and...