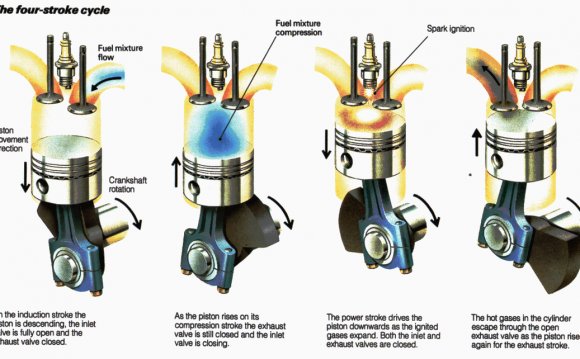

A two-stroke, or two-cycle, engine is a type of internal combustion engine which completes a power cycle with two strokes (up and down movements) of the piston during only one crankshaft revolution. This is in contrast to a "four-stroke engine", which requires four strokes of the piston to complete a power cycle. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time.

Two-stroke engines often have a high power-to-weight ratio, usually in a narrow range of rotational speeds called the "power band". Compared to four-stroke engines, two-stroke engines have a greatly reduced number of moving parts, and so can be more compact and significantly lighter.

The first commercial two-stroke engine involving in-cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two-stroke engines, his had a separate charging cylinder. The crankcase-scavenged engine, employing the area below the piston as a charging pump, is generally credited to Englishman Joseph Day. The first truly practical two-stroke engine is attributed to Yorkshireman Alfred Angas Scott, who started producing twin-cylinder water-cooled motorcycles in 1908.

Gasoline (spark ignition) versions are particularly useful in lightweight or portable applications such as chainsaws and motorcycles. Despite that, they are also used in diesel compression ignition engines operating in large, weight-insensitive applications, such as marine propulsion, railway locomotives and electricity generation. In a two-stroke engine, the heat transfer from the engine to the cooling system is less than in a four-stroke, which means that two-stroke engines can be more efficient. However, crankcase-compression two-stroke engines, such as the common small gasoline-powered engines, create more exhaust emissions than four-stroke engines because their petroil lubrication mixture is also burned in the engine, due to the engine's total-loss oiling system.

Applications[edit]

The two-stroke petrol (gasoline) engine was very popular throughout the 19th-20th century in motorcycles and small-engined devices, such as chainsaws and outboard motors. They were also used in some cars, a few tractors and many ships. Part of their appeal was their simple design (and resulting low cost) and often high power-to-weight ratio. The lower cost to rebuild and maintain made the two stroke engine very popular, until for the USA their EPA mandated more stringent emission controls in 1978 (taking effect in 1980) and in 2004 (taking effect in 2005 and 2010). The industry largely responded by switching to four-stroke petrol engines, which emit less pollution. Most small designs use petroil (two-stroke oil)) lubrication, with the oil being burned in the combustion chamber, causing "blue smoke" and other types of exhaust pollution. This is a major reason why two-stroke engines were replaced by four-stroke engines in many applications.

Simple two-stroke petrol engines continue to be commonly used in high-power, handheld applications such as string trimmers and chainsaws. The light weight, and light-weight spinning parts give important operational and safety advantages. For example, a four-stroke engine to power a chainsaw operating in any position would be much more expensive and complex than a two-stroke engine that uses a gasoline-oil mixture.

These engines are preferred for small, portable, or specialized machine applications such as outboard motors, high-performance, small-capacity motorcycles, mopeds, underbones, scooters, tuk-tuks, snowmobiles, karts, ultralights, model airplanes (and other model vehicles), lawnmowers, chain saws, weed-wackers and dirt bikes.

A number of mainstream automobile manufacturers have used two-stroke engines in the past, including the Swedish Saab and German manufacturers DKW and Auto-Union. The Japanese manufacturer Suzuki did the same in the 1970s. Production of two-stroke cars ended in the 1980s in the West, but Eastern Bloc countries continued until around 1991, with the Trabant and Wartburg in East Germany. Lotus of Norfolk, UK, has a prototype direct-injection two-stroke engine intended for alcohol fuels called the Omnivore which it is demonstrating in a version of the Exige. As this uses direct fuel injection, there are dramatic decreases in emission levels and increases in fuel efficiency.

Different two-stroke design types[edit]

A two-stroke engine, in this case with an expansion chamber illustrates the effect of a reflected pressure wave on the fuel charge. This is important for maximum charge pressure (volumetric efficiency) and fuel economy. It is used on most high-performance engine designs.Although the principles remain the same, the mechanical details of various two-stroke engines differ depending on the type. The design types vary according to the method of introducing the charge to the cylinder, the method of scavenging the cylinder (exchanging burnt exhaust for fresh mixture) and the method of exhausting the cylinder.

Piston-controlled inlet port[edit]

Piston port is the simplest of the designs and the most common in small two-stroke engines. All functions are controlled solely by the piston covering and uncovering the ports as it moves up and down in the cylinder. In the 1970s, Yamaha worked out some basic principles for this system. They found that, in general, widening an exhaust port increases the power by the same amount as raising the port, but the power band does not narrow as it does when the port is raised. However, there is a mechanical limit to the width of a single exhaust port, at about 62% of the bore diameter for reasonable ring life. Beyond this, the rings will bulge into the exhaust port and wear quickly. A maximum is 70% of bore width is possible in racing engines, where rings are changed every few races. Intake duration is between 120 and 160 degrees. Transfer port time is set at a minimum of 26 degrees. The strong low pressure pulse of a racing two-stroke expansion chamber can drop the pressure to -7 PSI when the piston is at bottom dead center, and the transfer ports nearly wide open. One of the reasons for high fuel consumption in 2-strokes is that some of the incoming pressurized fuel/air mixture is forced across the top of the piston, where it has a cooling action, and straight out the exhaust pipe. An expansion chamber with a strong reverse pulse will stop this out-going flow. A fundamental difference from typical four-stroke engines is that the two-stroke's crankcase is sealed and forms part of the induction process in gasoline and hot bulb engines. Diesel two-strokes often add a Roots blower or piston pump for scavenging.

Reed inlet valve[edit]

The reed valve is a simple but highly effective form of check valve commonly fitted in the intake tract of the piston-controlled port. They allow asymmetric intake of the fuel charge, improving power and economy, while widening the power band. They are widely used in motorcycle, ATV and marine outboard engines.

Rotary inlet valve[edit]

Another form of rotary inlet valve used on two-stroke engines employs two cylindrical members with suitable cutouts arranged to rotate one within the other - the inlet pipe having passage to the crankcase only when the two cutouts coincide. The crankshaft itself may form one of the members, as in most glow plug model engines. In another embodiment, the crank disc is arranged to be a close-clearance fit in the crankcase, and is provided with a cutout which lines up with an inlet passage in the crankcase wall at the appropriate time, as in the Vespa motor scooter.

The advantage of a rotary valve is it enables the two-stroke engine's intake timing to be asymmetrical, which is not possible with piston port type engines. The piston port type engine's intake timing opens and closes before and after top dead center at the same crank angle, making it symmetrical, whereas the rotary valve allows the opening to begin earlier and close earlier.

RELATED VIDEO

Kick start refers to a method of starting an internal combustion engine (usually that of a motorcycle) by pushing a ratcheting lever with one's foot. Kick start mechanisms were almost universally a part of motorcycle engines before the mid-1970s, and were phased out...

Kick start refers to a method of starting an internal combustion engine (usually that of a motorcycle) by pushing a ratcheting lever with one's foot. Kick start mechanisms were almost universally a part of motorcycle engines before the mid-1970s, and were phased out...

A chainsaw (or chain saw) is a portable mechanical saw, powered by electricity, compressed air, hydraulic power, or most commonly a two-stroke engine. It is used in activities such as tree felling, limbing, bucking, pruning, by tree surgeons to fell trees and remove...

A chainsaw (or chain saw) is a portable mechanical saw, powered by electricity, compressed air, hydraulic power, or most commonly a two-stroke engine. It is used in activities such as tree felling, limbing, bucking, pruning, by tree surgeons to fell trees and remove...