The internal combustion engine is a throwback. It is a holdover from the age of steam. Its details have been refined, its materials improved and its output multiplied, but the basic mechanism—a piston moving up and down in a cylinder bore—was invented before the phonograph or the lightbulb.

The product of an era of cheap, abundant energy, the combustion engine is also flagrantly wasteful. In a four-stroke gasoline engine—the engine that is most likely in your car, your motorboat, maybe even your generator—a piston is first driven downward, sucking air into the cylinder. Next, the piston makes an upward stroke that compresses the air; then a spark ignites the fuel-air mixture, which explodes, thrusting the piston downward. The final upward stroke pushes out the spent mixture. In that cycle of four piston strokes, today’s gasoline engine typically converts 14 to 30 percent of the energy stored in fuel into useful work. The rest is lost as heat and friction.

Installing that engine in a vehicle compounds the waste. Accessories such as water pumps and air-conditioning compressors draw energy without contributing to forward motion. Rolling resistance of the tires wastes fuel, as does friction in bearings and transmission gears. Aerodynamic drag forces the engine to work hard just to maintain a steady highway speed. All told, the car you drive puts about 20 percent of the fuel’s energy to work in driving down the road. Clearly, this petroleum-swilling greenhouse-gas machine is overdue for a disruption. It’s no wonder that each new electric car, breakthrough in battery chemistry, or promise of mass-produced fuel cell vehicles sounds like a death announcement for the internal combustion engine.

Electric cars seem poised to put the last nails in the coffin. With few moving parts to generate friction, electric motors are vastly more efficient—turning as much as 96 percent of the energy they consume into useful work. They give up very little waste heat, and, if fed via alternative energy, can produce emission-free power. Besides, a car powered with an electric motor has clear design advantages. Its nearly flat torque curve (pounds-feet graphed against engine rotational speed) means it does not need a complex transmission, reducing cost and boosting efficiency at the same time. Combustion engines usually need to spin at several thousand revolutions per minute (rpm) to produce peak torque, but electric engines burst into maximum torque the moment the shaft turns. That’s what gives electric cars and hybrids such a satisfying snap away from a stop.

For all these reasons, the case against the piston engine is clear. Its days seem to be numbered. But the reality is that internal combustion is not going anywhere soon. Don’t tell Elon Musk, but the heat engine, to use the handy moniker, will probably rule the roads until at least 2050.

The persistence of the combustion engine can’t be blamed just on market inertia or the power of Big Oil. It endures—and dominates—because it is so adaptable. Tiny versions power yard trimmers and chainsaws. Huge, highly efficient models propel bulldozers and cargo ships. In a car, this engine can be configured as a mild-mannered gas sipper or a high-revving race device.

It is beautifully suited for transportation, because it exploits a fuel that is supremely portable and energy-dense. “Liquid hydrocarbons are liquid gold, ” says John B. Heywood, a mechanical engineer who is the Sun Jae Professor Emeritus at M.I.T. The gasoline engine refuels in minutes, after which it can cover 400 to 500 miles. And fuels, too, are adaptable: During the last century, as roads improved and cars began going faster, gasoline was re-engineered to help engines extract its energy.

In short, the long, rich life of the gasoline engine is the outcome of what paleoanthropologist Rick Potts calls variability selection: The idea that in a rapidly changing environment, only the versatile survive. Potts, an expert in human origins with the Smithsonian Institute, thinks that early hominids prevailed because they were flexible. The climate our ancestors confronted during the early Pleistocene fluctuated dramatically, with frequent shifts in temperature, water supply, food sources, vegetation, and competition. They survived this time of turmoil because they were generalists, says Potts. With long arms and long legs, they could climb trees in the forest or walk for miles across savannah. With big brains, they could figure out how to adapt to changing circumstances, and invent social systems and technologies to help them cope. They weren’t faster or stronger or more efficient than other creatures—they were more adaptable.

The piston engine looks like another example of survival through adaptability. It is cheap to build, has conformed to the requirements of various fuels and physical layouts, and has advanced in lockstep with developments in metallurgy and pollution control. Continual refinements mean that today’s internal combustion engine emits 99 percent less pollution than its progenitors in the 1960s. In regions with poor air quality, automakers remind us, today’s engines actually push cleaner air out through the tailpipe than they ingest. Today, confronted with the task of reducing carbon dioxide emissions and reining in energy use, the engineers, industry experts, and investors who know engines best are far from giving up on internal combustion. In fact, they’re upping their investment. This old technology has a lot of miles left in it yet.

RELATED VIDEO

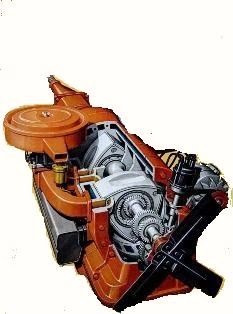

The General Motors Rotary Combustion Engine (GMRCE) is an internal combustion Wankel engine which uses a rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. In November 1970, GM paid $50 million for initial licenses to...

The General Motors Rotary Combustion Engine (GMRCE) is an internal combustion Wankel engine which uses a rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. In November 1970, GM paid $50 million for initial licenses to...

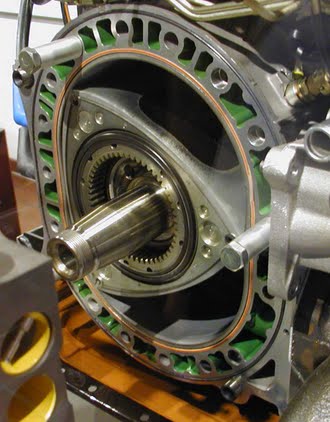

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like...

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like...