Horizontal steam engine. The piston is shown at D. The three piston rings prevent steam from escaping between chambers A and B.

Piston ring. The piston ring (PR) is a split band pressed against the wall of the cylinder by springs (S) mounted in the inner "junk ring" (JR). The tongue (T) maintains the seal as the ring expands and splits apart. Spring-loaded piston rings.A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.

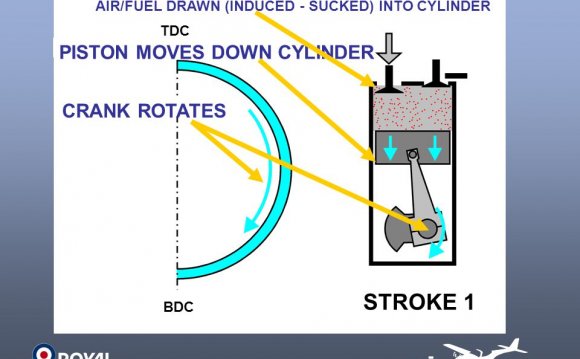

The three main functions of piston rings in reciprocating engines are :

- Sealing the combustion chamber so that there is no transfer of gases from the combustion chamber to the crank.

- Regulating engine oil consumption.

The gap in the piston ring compresses to a few thousandths of an inch when inside the cylinder bore. Piston rings are a major factor in identifying if an engine is two stroke or four stroke. Three piston rings suggest that it is a four stroke engine while two piston rings suggest that it is a two stroke engine.

History[edit]

The split piston ring was invented by John Ramsbottom who reported the benefits to the Institution of Mechanical Engineers in 1854. It soon replaced the hemp packing hitherto used in steam engines. The use of piston rings at once dramatically reduced the frictional resistance, the leakage of steam, and the mass of the piston, leading to significant increases in power and efficiency and longer maintenance intervals.

Automotive[edit]

Piston rings have been an area of considerable focus and development for internal combustion engines. The needs of diesel engines and small piston-ported two-stroke engines have been particularly difficult. Piston rings may account for a considerable proportion of the total friction in the engine, as much as 24%. This high friction is a result of the design compromises needed to achieve good sealing and long lifetime. Sealing is achieved by multiple rings, each with their own function, using a metal-on-metal sliding contact.

Rings are also sprung to increase this contact force and maintain a close seal, either by the stiffness of the ring itself or by a separate spring behind the seal ring. It is important that rings float freely in their grooves within the piston, so that they can stay in contact with the cylinder. Rings binding in the piston, usually due to a build-up of either combustion products or a breakdown of the lubricating oil is a common cause of failure, especially for diesel engines.

Lubrication of piston rings is difficult and has been a driving force to improvements in the quality of motor oil. The oil must survive high temperatures and harsh conditions with a high-speed sliding contact. Lubrication is particularly difficult as the rings have an oscillating motion rather than continuous rotation, as for a bearing journal. At the limits of piston movement, the ring stops and reverses direction. This disrupts the normal oil wedge effect of a hydrodynamic bearing, leading to pronounced wear and the formation of a 'step' in the cylinder bore around the height of the upper ring. Noting that some sleeve valve engines suffered far less from such wear, complex designs such as a rotating cylinder liner have been considered, just to address this problem.

Most automotive pistons have three rings: The top two while also controlling oil are primarily for compression sealing (compression rings); the lower ring is for controlling the supply of oil to the liner which lubricates the piston skirt and the compression rings (oil control rings). At least two piston rings are found on most piston and cylinder combination. Typical compression ring designs will have an essentially rectangular cross section or a keystone (right angled trapezoidal) cross section. The periphery will then have either a barrel profile (top compression rings) or a taper napier form (second compression rings or scraper rings). There are some taper faced top rings and on some old engines simple plain faced rings were used.

Oil control rings typically are of three types:

- helical spring backed cast iron or steel

- multipiece steel

The spring backed oil rings and the cast iron oil rings have essentially the same range of peripheral forms which consist of two scraping lands of various detailed form. The multipiece oil control rings usually consist of two rails or segments (these are thin steel rings) with a spacer expander spring which keeps the two rails apart and provides the radial load.

The piston might be a fairly loose fit in the cylinder. If it were a tight fit, it would expand as it got hot and might stick tight in the cylinder. If a piston sticks (seizes) it could cause serious damage to the engine. On the other hand, if there is too much clearance between the piston and cylinder walls, much of the pressure from the burning gasoline vapour will leak past the piston (a condition known as blow-by) and into the crankcase, and the push on the piston from combustion will be much less effective in delivering power.

Wear due to ring load on the bore[edit]

Piston rings are subject to wear as they move up and down the cylinder bore due to their own inherent load and due to the gas load acting on the ring. To minimize this, they are made of wear-resistant materials, such as cast iron and steel, and are coated or treated to enhance the wear resistance. Two-stroke port design is critical to ring life. Newer modern motorcycle manufacturers have many single function but serrated ports to retain the ring. Typically, top ring and oil control rings will be coated with chromium, or Nitrided, possibly plasma sprayed or have a PVD (physical vapour deposition) ceramic coating. For enhanced scuff resistance and further improved wear, most modern diesel engines have top rings coated with a modified chromium coating known as CKS or GDC, a patent coating from Goetze which has aluminium oxide or diamond particles respectively included in the chrome surface. The lower oil control ring is designed to leave a lubricating oil film, a few micrometres thick on the bore, as the piston descends. Three piece oil rings, i.e. with two rails and one spacer, are used for four-stroke gasoline engines.

RELATED VIDEO

Two-and-four stroke engines are engines that combine elements from both two-stroke and four-stroke engines. They usually incorporate two pistons.

Two-and-four stroke engines are engines that combine elements from both two-stroke and four-stroke engines. They usually incorporate two pistons.