By: John Fyffe

By: John Fyffe

Internal combustion (IC) engines have been around for more than 150 years and helped usher in the industrial age. With the rapid change of technology in the world today, one might suspect that IC engines will soon be a thing of the past, replaced by newer, better technologies. While no one knows the answer yet, a strong case can still be made for the future of the IC engine. Research and development efforts are on-going to make modern IC engines more efficient, more environmentally friendly, more powerful, and capable of accepting a wider range of fuels.

Modern Engines

Most Americans are familiar with the spark ignition (SI) engines found in most passenger cars in the US. Spark ignition engines induct a mixture of fuel and air into the cylinder which is compressed and then ignited by a spark to create a flame that will sweep across the cylinder to burn all of the fuel. This process converts the chemical energy in the fuel into sensible energy (increasing the temperature and pressure) that can be extracted in the form of work, usually to propel a car. SI engines are still prominent because of their low cost, ease of use, and ability to meet a large dynamic range of loads (idle, city driving, highway driving, etc).

Compression ignition (CI) engines, commonly referred to as Diesel engines, are primarily used for heavy-duty transportation in the US, although they do make up a large portion of the light-duty market in Europe as well. Diesel engines differ from SI engines in that they induct only air into the cylinder and combustion occurs spontaneously, without the help of a spark – the mixture is said to autoignite – when fuel is injected directly into the compressed air. Diesel engines can have higher compression ratios (CR), and therefore higher efficiencies, than SI engines because they avoid the problem of knock. Knock occurs in SI engines when the flame from the spark compresses the unburned mixture that then explodes, creating a shockwave that causes engine damage (and the metallic “knocking” sound). Another reason Diesel engines can have higher efficiencies is that they do not need to throttle the inlet air (which requires work from the engine) like SI engines.

Typical IC engines have peak efficiencies between 30 – 40%. However, engines are operated over a wide range of conditions – idling, accelerating, cruising, and stop-and-go – making the engine operate away from its ideal efficiency point. Under normal driving conditions the average efficiency of IC engines drops to approximately 20%. This is significantly lower than typical electricity-generating power plants that are between 35-55% efficient, but IC engines in cars do operate under a more restrictive set of constraints, primarily the large range of operating conditions, small sizes, and low weight requirements.

Hybrid engine technology has developed rapidly in the past couple of decades, leading to improvements in efficiency and reduction in total emissions. Hybrids use battery powered electric motors to achieve the large dynamic driving range required while keeping the IC engine close to its most efficient operating point. For example, when a driver is merging onto the highway and “steps on it”, the car requires more power than the IC engine produces at its peak efficiency, so the battery powered electric motor kicks in and helps accelerate the car. But, if the driver ends up getting stuck in traffic and is only moving along at a few miles per hour, the engine is producing too much power at the maximum efficiency point. Therefore, instead of reducing the power output of the engine (and reducing the efficiency at which it is producing power), the hybrid operates the electric motor in reverse, making the “motor” a generator. Therefore, the engine can operate at peak efficiency, meet the driver’s demand of slogging through traffic, and store excess energy in the battery system on board to be used again when traffic clears up. Hence, hybrids can operate more efficiently than vehicles with only IC engines.

Therefore, instead of reducing the power output of the engine (and reducing the efficiency at which it is producing power), the hybrid operates the electric motor in reverse, making the “motor” a generator. Therefore, the engine can operate at peak efficiency, meet the driver’s demand of slogging through traffic, and store excess energy in the battery system on board to be used again when traffic clears up. Hence, hybrids can operate more efficiently than vehicles with only IC engines.

The Continued Evolution of IC Engines

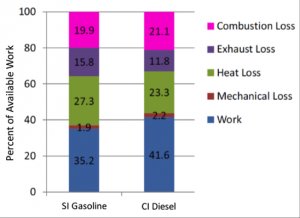

Moving forward, researchers are continuing to target efficiency and emissions improvements in IC engines. Because they are ubiquitous, reliable, flexible devices, improving them further is an important endeavor. As we try to improve IC engines, it’s important to understand where the inefficiencies arise. Figure 1 shows the breakdown of where the incoming energy from fuel that is available for work output is going. A typical IC engine will lose 20% of its available work to the combustion process, 27% is transferred out as heat, and 16% is transferred out with the exhaust. This leaves only 35% of the energy available as work to move the vehicle. Maximizing the work output therefore can be accomplished by reducing the heat transfer, extracting the available energy from the exhaust, and reducing the inefficiency associated with combustion. Reducing losses due to heat transfer and exhaust are more easily tackled with current technologies. The combustion loss is typically thought of as a sunk cost, however research done in the Advanced Energy Systems Lab (AESL) at Stanford shows that increased efficiencies can be achieved by combusting at higher energy states, referred to as the extreme states principle. Our lab has shown that when the air/fuel mixture is combusted at higher and higher temperatures and pressures – for instance, in our experimental IC engine with a 100:1 compression ratio – the air/fuel mixture becomes extremely energetic which reduces entropy generation during combustion, i.e. reducing the combustion losses. While a 100:1 is not necessarily practical – the temperatures and pressures in such an engine would vastly exceed those in conventional IC engines – it demonstrates the extreme states principle and a method of reducing combustion losses.

RELATED VIDEO