New cars are confusing. With all the computers, sensors, and gadgets, it may seem like there's some sort of magical witchcraft taking place under the hood. We're here to show you how modern automotive computer control systems work. Last time, we looked at Electronic Throttle Control. Today's topic: Variable Valve Timing.

New cars are confusing. With all the computers, sensors, and gadgets, it may seem like there's some sort of magical witchcraft taking place under the hood. We're here to show you how modern automotive computer control systems work. Last time, we looked at Electronic Throttle Control. Today's topic: Variable Valve Timing.

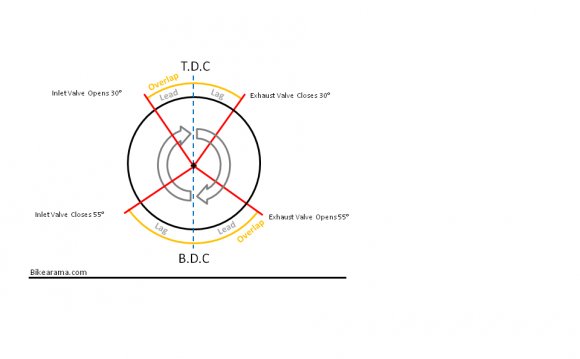

Back in the day, a car's intake and exhaust valves opened a specific amount at a specific point in the four stroke cycle, and for a specific amount of time. It was that simple. Nowadays, however, many engines can not only change when their valves open, but also how much they open and for how long – that is, new cars can change valve timing, valve lift, and valve duration. Let's have a look at how this all works. For a lot of you this is review, but if we want a new generation of car enthusiasts to care about cars, it can't hurt to explain how they actually work.

VARIABLE VALVE TIMING

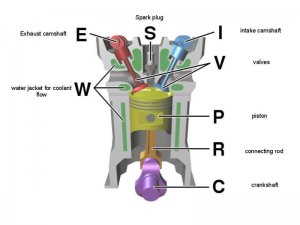

A typical engine's intake and exhaust valves are opened via the lobes on a camshaft. With dual overhead cam engines, there are separate camshafts for exhaust valves and intake valves. These camshafts are made of hardened iron or steel and are connected to the crankshaft via timing belts, chains, or gears. Since modern gasoline engines incorporate the four-stroke cycle, this means that the camshafts rotate once for every two crankshaft rotations. To reinforce this point, consider the intake stroke of an engine. The intake valve is open, meaning the camshaft lobe is pushing against the cam follower and opening the valve. Lets trace the motion of this cam lobe and compare it to the motion of the crankshaft.

While the intake valve is open, the piston moves down toward bottom dead center. Once the engine has reached bottom dead center, the crankshaft has rotated 180 degrees. Then the piston moves up to compress the fuel mixture. Once the piston has reached top dead center, the crankshaft has made a full rotation. Next, the spark plug ignites the fuel mixture, sending the piston back down to bottom dead center. At this point, the crankshaft has turned one and a half full rotations. Now the exhaust valve opens, and the piston moves back up to top dead center. The crankshaft has rotated two full revolutions. Now that the piston is at approximately top dead center, the camshaft lobe that we are monitoring comes back around and opens the intake valve and the piston moves back down. Thus, after two revolutions of the crankshaft, the camshaft has rotated once. Check out this gif to see it all in motion.

The crankshaft has rotated two full revolutions. Now that the piston is at approximately top dead center, the camshaft lobe that we are monitoring comes back around and opens the intake valve and the piston moves back down. Thus, after two revolutions of the crankshaft, the camshaft has rotated once. Check out this gif to see it all in motion.

In the 1960s, automakers began developing variable valve timing systems that allowed intake and exhaust valves to open earlier or later in the 4-stroke cycle. The aim was to improve volumetric efficiency, decrease NOx emissions, and decrease pumping losses. Today, there are two major types of variable valve timing: cam phasing and cam changing. With cam changing, the ECU selects a different cam profile based on engine load and speed, whereas with cam phasing, an actuator rotates the camshaft, changing the phase angle. There are dozens of ways to go about varying valve timing, lift, and duration, so we're just going to look at Toyota's VVT-i, and Honda's VTEC.

RELATED VIDEO