The original Atkinson-cycle piston engine allowed the intake, compression, power, and exhaust strokes of the four-stroke cycle to occur in a single turn of the crankshaft and was designed to avoid infringing certain patents covering Otto-cycle engines. Due to the unique crankshaft design of the Atkinson, its expansion ratio can differ from its compression ratio and, with a power stroke longer than its compression stroke, the engine can achieve greater thermal efficiency than a traditional piston engine. While Atkinson's original design is no more than a historical curiosity, many modern engines use unconventional valve timing to produce the effect of a shorter compression stroke/longer power stroke, thus realizing the fuel-efficiency improvements the Atkinson cycle can provide.

Atkinson differential engine[edit]

Patent drawing of the Atkinson differential engine Animation of the Atkinson differential engineThe first implementation of the Atkinson cycle was in 1882; unlike later versions, it was arranged as an opposed piston engine, the Atkinson differential engine. In this, a single crankshaft was connected to two opposed pistons through a toggle jointed linkage that had a non-linearity; for half a revolution one piston remained almost stationary while the other approached it and returned, and then for the next half revolution the pistons changed over which piston was almost stationary and which piston approached and returned. Thus, in each revolution, one piston provided a compression stroke and a power stroke, and then the other piston provided an exhaust stroke and a charging stroke. As the power piston remained withdrawn during exhaust and charging, it was practical to provide exhaust and charging using valves behind a port that was covered during the compression stroke and the power stroke, and so the valves did not need to resist high pressure and could be of the simpler sort used in many steam engines, or even reed valves.

Ideal thermodynamic cycle[edit]

Figure 1: Atkinson Gas CycleThe ideal Atkinson cycle consists of following operations:

Modern Atkinson-cycle engines[edit]

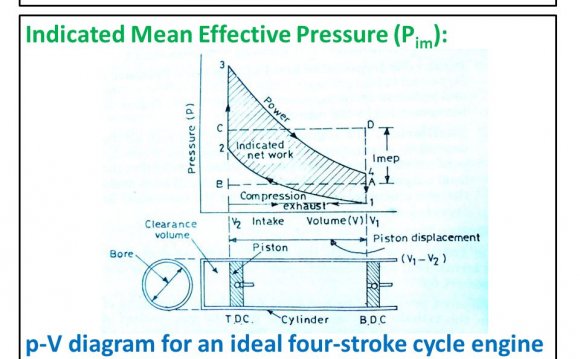

A small engine with Atkinson-style linkages between the piston and flywheel. Modern Atkinson-cycle engines do away with this complex energy path.Recently, the term "Atkinson cycle" has been used to describe a modified Otto-cycle engine in which the intake valve is held open longer than normal to allow a reverse flow of intake air into the intake manifold. The effective compression ratio is reduced (for a time the air is escaping the cylinder freely rather than being compressed), but the expansion ratio is unchanged. This means the compression ratio is smaller than the expansion ratio. Heat gained from burning fuel increases the pressure, thereby forcing the piston to move, expanding the air volume beyond the volume when compression began. The goal of the modern Atkinson cycle is to allow the pressure in the combustion chamber at the end of the power stroke to be equal to atmospheric pressure; when this occurs, all the available energy has been obtained from the combustion process. For any given portion of air, the greater expansion ratio allows more energy to be converted from heat to useful mechanical energy, meaning the engine is more efficient.

The disadvantage of the four-stroke Atkinson-cycle engine versus the more common Otto-cycle engine is reduced power density. Due to a smaller portion of the compression stroke being devoted to compressing the intake air, an Atkinson-cycle engine does not take in as much air as would a similarly designed and sized Otto-cycle engine.

RELATED VIDEO