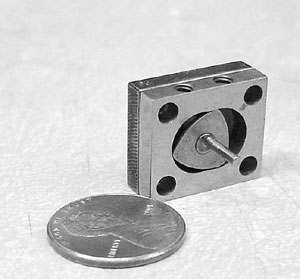

Engineers create worlds smallest rotary internal combustion engine

By Catherine Zandonella, Public Affairs

Berkeley engineers have created the worlds smallest combustion engine, which is slightly larger than a penny.

Berkeley engineers have created the worlds smallest combustion engine, which is slightly larger than a penny.

| The smallest engine of its kind anywhere in the world, created in a Berkeley laboratory, could someday replace batteries as an efficient power source for mobile devices like laptop computers. Not much bigger than a stack of pennies, the mini engine is the first engine of its size to deliver power on a continuous basis. Fashioned from steel, the engine is also a prototype for a Berkeley endeavor to create an even smaller engine chemically etched from silicon. We are at the frontier of research into how to generate power using the smallest of components, said Carlos Fernandez-Pello, a mechanical engineering professor who developed the engine with the help of Kenji Miyaska of Fukui University in Japan, Berkeley post-doctoral researcher David Walther and graduate students Kelvin Fu, Aaron Knobloch and Fabian Martinez. At present, the engine can produce up to 2.5 watts of electricity, enough to power a bicycle headlamp. But Fernandez-Pello and his team are ramping up the engine to produce 30 watts, enough to power a weak light bulb, but plenty to power electronic devices. Like the engine in your car, the mini engine produces motion from controlled combustion, which takes place when a fuel such as gasoline is combined with oxygen and a spark in a chamber. The released energy drives a rotor, which can be attached to a gear system to make automobile wheels turn or drive other machinery. The mini engine is designed to run on liquid hydrocarbon fuels such as butane or propane, chemical cousins of gasoline. One fluid ounce of fuel will keep the motor running for two hours. Once it is optimized, the tiny engine will be able to run 10 times longer than a conventional lithium ion battery. The motor and fuel together weigh only a fraction of the weight of a standard battery used in a digital camera. Called a rotary engine or Wankel engine after its inventor, this design has not been as widely used as the piston-style engine found in most cars today, although it did appear in some models of the Mazda RX-7 and is reappearing in the concept cars of tomorrow. The Berkeley team hopes that some day the mini engine can be used to power electronic devices, like computers or robots. Fernandez-Pello sees it as a first step in designing much smaller engines made using micro-electromechanical (MEMS) technology. The mini engine design is ideal for miniaturizing because of its simplicity, and the components are relatively easy to make using silicon etching technology. The size of a pinhead, such a miniaturized engine will be made from parts etched out of silicon in a process similar to that used to make computer microprocessors. In this process, light is used to burn away areas of silicon until only the desired shape remains. The researchers envision a micro engine capable of producing power for cell phones and other small electronic devices. This truly tiny engine will have proportions similar to those of the steel mini engine, but would use about one-thousandth of an ounce of fuel for two hours of operating time. |

RELATED VIDEO