The internal combustion engine is a system in which the combustion of the fuel occurs in a chamber within the system. When the fuel burns inside the combustion chamber, high pressure and high temperature gases are produced. These gases exert a direct force on the walls of the combustion chamber. This linear force is converted into useful rotational motion by a connecting rod and a crankshaft mechanism. This favors the.

There are two types of internal combustion engines. They are,

- Four Stroke Internal Combustion Engine

- Two Stroke Internal Combustion Engine

A lot of research work was carried out in the 20th century to get the maximum utilization of heat and to convert it into useful work. As a result we have IC engines. As per the second law of thermodynamics, energy cannot be completely converted into useful work but the idealized device of Carnot heat engine is designed to help us overcome this problem to a large extent. Carnot engine basically uses the heat to convert it into useful work in a cyclical or repetitive manner.

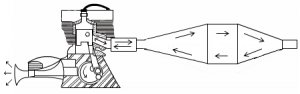

Internal Combustion Engine diagram

In a two stroke internal combustion engine, valves are replaced by ports. The power stroke occurs for each rotation of the crankshaft. For one complete cycle, the crankshaft makes one full rotation. The specialty of a 2 stroke internal combustion engine is that two strokes are performed at a time.

In a two stroke internal combustion engine, valves are replaced by ports. The power stroke occurs for each rotation of the crankshaft. For one complete cycle, the crankshaft makes one full rotation. The specialty of a 2 stroke internal combustion engine is that two strokes are performed at a time.

Down stroke

As the piston moves downwards, it compresses the air fuel mixture present in the crankcase. Due to this applied pressure, the air-fuel mixture moves into the cylinder through the transfer port. This mixture drives the exhaust gases out of the cylinder through the exhaust port which is uncovered by the downward motion of the piston. The intake port stops the air-fuel mixture from entering the crankcase. Both intake and exhaust strokes happen simultaneously.

Upstroke

As the piston moves upwards, it compresses the air fuel mixture in the cylinder. As the piston comes close to the TDC, a spark ignites the fuel. This explosion produces high pressure hot gases which induces a linear force on the piston. This linear force has to be converted into rotational movement by using connecting rod and crankshaft. Both combustion and compression strokes happen simultaneously.

From the moment the fuel enters the combustion chamber till it exits, it has to go through four stages of combustion. These four stages are,

Intake stroke

At the start of the cycle, the piston will be at the TDC (Top dead center). As the piston moves towards BDC (Bottom dead center), the inlet valve opens which allows the air-fuel mixture to gush inside the chamber.

Compression stroke

The piston moves towards TDC from BDC. While moving upwards, the piston compresses the air-fuel mixture. As the air-fuel mixture is compressed, it attains high pressure and temperature.

Power stroke

A spark is produced at the TDC by the spark plug, which ignites the compressed air-fuel mixture. This creates an explosion in the combustion chamber. This force pushes the piston towards BDC. This is also known as combustion stroke.

Exhaust stroke

Once the piston hits the BDC, due to inertia of the force produced in previous cycle, it moves upwards. The exhaust valve opens and the waste gas is pushed outside the combustion chamber. Thus, to complete one cycle from intake stroke to exhaust stroke, the fuel has to go through four stages. Hence, it is called a four stroke engine. During this cycle, the crankshaft makes two full rotations, half rotation in each cycle.

The depleting fossil fuel resources and increasing exhaust fumes in the atmosphere created a need for finding different fuels for the IC engines. Hydrogen finds a place as one such fuel which was first used as submarine fuel in Japan. The conventional internal combustion engines are redesigned to suite the fuel.

High temperature withstanding non-platinum tipped spark plugs, hardened valves and valve seats, stronger connecting rods, higher voltage ignition coil, fuel injection devices designed for a gas instead of a liquid, larger crankshaft damper, stronger head gasket material and modified exhaust designs are some major differences from the conventional fossil fuel using designs. Hydrogen being a very light gas, is difficult to store in the fuel tank. Liquid hydrogen requires high insulation, while as gas, it's storage requires a large tank. Using hydrogen generators like hydrazine or sodium boro hydride releases exhausts which are poisonous.

In the process of oxidation also direct compressed air oxidation utilizing the vast availability of atmospheric air, the reaction between oxygen and hydrogen at that high temperature generated by the reaction between hydrogen and oxygen results in the production of NO.

2 + O2 → 2NO

In torpedoes, they use a mixture of liquid oxygen and liquid air to limit the production of NO. Another aspect of hydrogen engines is the controlled explosion in the engine. Due to this reason hydrogen fuel internal combustion engines are used only for super heavy machinery like Rockets.Research is going on to find a controlled reaction method by using hydrogen carrying catalysts, instant hydrogen producing methods, using NO in excess of oxygen, hydrogen peroxide, etc.The internal combustion engine was first patented in 1861, but the first person to actually build a car with this engine was a German engineer named Nicolaus Otto (1832-1891). The four stroke principle of operation is today commonly known as the Otto cycle and four-stroke engines using spark plugs are often referred to as Otto engines.

The Otto cycle consists of

- Adiabatic compression

- Heat addition at constant volume

- Adiabatic expansion

- Rejection of heat at constant volume.

- Internal combustion engines are most commonly used in a variety of transport vehicles, power generation units such as in vehicles, boats, aircraft, generators, lawn movers and locomotives.

- Internal combustion engine are most useful where very high power-weight ratio, noise restriction

RELATED VIDEO

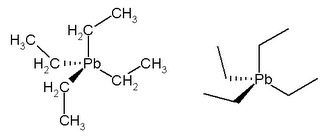

Tetraethyllead (common name tetraethyl lead), abbreviated TEL, is an organolead compound with the formula (CH3CH2)4Pb. Its mixing with gasoline (petrol) as an inexpensive additive beginning in the 1920s allowed octane ratings and thus engine compression to be...

Tetraethyllead (common name tetraethyl lead), abbreviated TEL, is an organolead compound with the formula (CH3CH2)4Pb. Its mixing with gasoline (petrol) as an inexpensive additive beginning in the 1920s allowed octane ratings and thus engine compression to be...