RCCI is a dual fuel engine combustion technology that was developed at the University of Wisconsin-Madison Engine Research Center laboratories. RCCI is a variant of Homogeneous Charge Compression Ignition (HCCI) that provides more control over the combustion process and has the potential to dramatically lower fuel use and emissions.

RCCI is a dual fuel engine combustion technology that was developed at the University of Wisconsin-Madison Engine Research Center laboratories. RCCI is a variant of Homogeneous Charge Compression Ignition (HCCI) that provides more control over the combustion process and has the potential to dramatically lower fuel use and emissions.

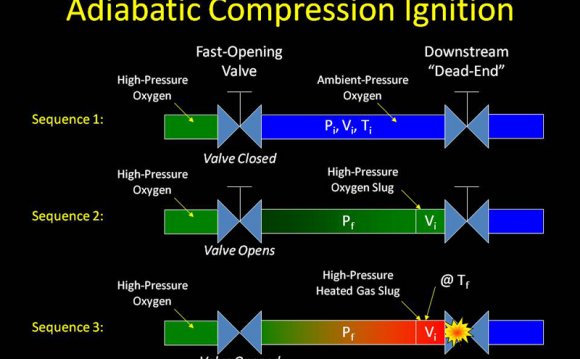

RCCI uses in-cylinder fuel blending with at least two fuels of different reactivity and multiple injections to control in-cylinder fuel reactivity to optimize combustion phasing, duration and magnitude. The process involves introduction of a low reactivity fuel into the cylinder to create a well-mixed charge of low reactivity fuel, air and recirculated exhaust gases. The high reactivity fuel is injected before ignition of the premixed fuel occurs using single or multiple injections directly into the combustion chamber. Examples of fuel pairings for RCCI are gasoline and diesel mixtures, ethanol and diesel, and gasoline and gasoline with small additions of a cetane-number booster (di-tert-butyl peroxide (DTBP)).

RCCI allows optimization of HCCI and Premixed Controlled Compression Ignition (PCCI) type combustion in diesel engines, reducing emissions without the need for after-treatment methods. By appropriately choosing the reactivities of the fuel charges, their relative amounts, timing and combustion can be tailored to achieve optimal power output (fuel efficiency), at controlled temperatures (controlling NOx) with controlled equivalence ratios (controlling soot). Key benefits of the RCCI strategy include:

- Lowered NOx and PM emissions

- Reduced heat transfer losses

- Increased fuel efficiency

- Eliminates need for costly after-treatment systems

- Complies with EPA 2010 emissions guidelines without exhaust after treatment

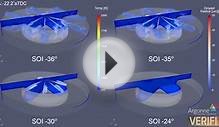

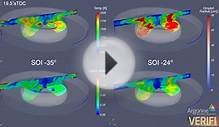

Example experimental engine results are shown in Figure 1. More details about RCCI can be found at the following web sites:

Figure 1: RCCI engine-out NOx, Soot and thermal efficiency in the ERC Caterpillar 3401 heavy-duty research diesel engine operating on a variety of fuel stocks, including gasoline/diesel. Indicted efficiencies as high as 59% achieved with E85/diesel. Note that emissions targets are met in-cylinder, without need for exhaust after-treatment.

RELATED VIDEO

The hot bulb engine, or hotbulb or heavy oil engine is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb.

The hot bulb engine, or hotbulb or heavy oil engine is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb.