The internal combustion engines are the engines in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine the expansion of the high temperature and high pressure gases produced by combustion apply direct force to some component of the engine. The force is applied typically to pistons, turbine blades or a nozzle.

Principle of operation:

Air-fuel mixture in the combustion chamber is ignited, either by a spark plug (in case of SI Engines) or by compression (in case of CI engines). This ignition produces tremendous amount of heat energy and pressure inside the cylinder. This induces reciprocating motion in the piston.

Power of the piston is transmitted to a crankshaft which undergoes rotary motion. The rotary motion is ultimately transmitted to the wheels of the vehicle, via a transmission system, to produce propulsion in the vehicle.As the combustion takes place internally inside the cylinder (a part of working fluid circuit) the engine is called internal combustion engine.

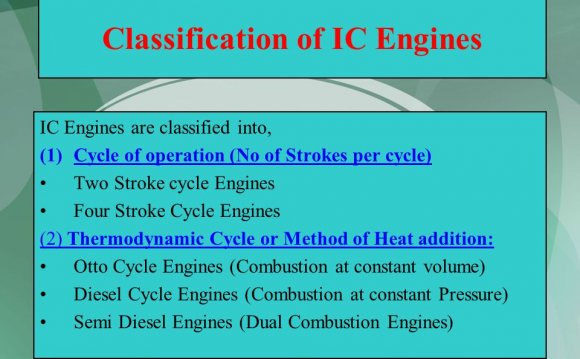

Classification of Internal Combustion Engines:

Today’s IC engines can be classified in several ways. Some of the ways of classification of Internal Combustion (IC) engines is listed below:

1. Based on application

Automobile Engine Aircraft Engine Locomotive Engine Marine Engine Stationary Engine2. Based on basic engine design

Reciprocating: Single cylinder, Multi-cylinder In-line, V, radial, opposed cylinder, Opposed Piston. Rotatory: Single motor, Multi motor3. Based on operating cycle

Dual (For the Actual Diesel Engine) Miller (For Early/Late Inlet valve closing type SI Engine)4. Based on working cycle

Four stroke cycle Two stroke cycle Scavenging ; direct/crankcase/cross flow; back flow/loop; Uni flow Naturally aspirated or turbocharged5. Based on Valve/port design and location

Design of valve/port Poppet valve Rotatory valve Location of valve/port6.Based on Fuel

Convectional Crude oil derivatives; Petrol, diesel Other sources; coal, bio-mass, tar stands, shale Alternative Petroleum derived: CNG, LPG Bio-mass derived: alcohols, vegetable oils, producer gas, biogas and hydrogen Blending Bi-fuel and dual fuel7. Based on mixture preparation

Carburetion Fuel injection8. Based on ignition

Spark ignition Compression Ignition9. Based on stratification of charge

Homogeneous Charge Stratified charge With carburetion With fuel injectionRELATED VIDEO