NR Ceramic Pistons (PRNewsFoto/NIAMA-REISSER, LLC) Ceramic Pistons Event. (PRNewsFoto/NIAMA-REISSER, LLC)

NR Ceramic Pistons (PRNewsFoto/NIAMA-REISSER, LLC) Ceramic Pistons Event. (PRNewsFoto/NIAMA-REISSER, LLC)

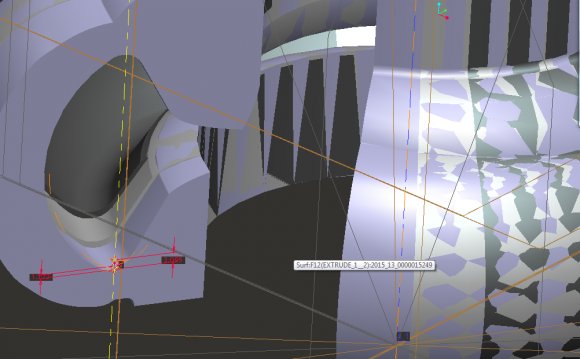

Heinz-Gustav Reisser, the CEO of the Company, says; "It's all about saving money. For that reason, we started the Metal-Ringless Ceramic Piston project in 2009." Since the initial kick-off, NIAMA-REISSER, LLC has been working diligently to create something that does not and never has existed in the internal combustion engine industry: Metal-Ringless Ceramic Internal Combustion Engine Pistons.

According to Reisser: "Our technology is no longer employing metal compression rings nor metal oil control rings." This reduces the frictional drag on the piston and further increases the longevity of the engine. Reducing the frictional drag on the piston increases any engine's thermal efficiency and performance.

The proprietary ceramic material enables the combustion to run hotter and burn more homogeneous, which further elevates the efficiency of any internal combustion engine.

Polymer rings are used to control the oil flow in 4-Stroke applications from the sump or crank case into the combustion chamber. For that matter, the piston mantel only boasts two polymer rings.

TO DEMONSTRATE THE INCREASE IN EFFICIENCY, the company is going to travel with two mechanically overhauled and identical Chevrolet Lumina APV vans (Van 1 has been retrofitted with NR-Metal-Ringless Ceramic Pistons vs. Van 2 has stock OEM Pistons) from –Columbus-, to –Detroit- . The Company will hold an INTRODUCTORY PRESENTATION at the , Inn Hotel at - and will return to the same venue at 7:30 PM for a SUMMARY PRESENTATION, after having released its EFFICIENCY RESULTS in a RESULTS PRESENTATION at the Comfort, Inn Hotel in – .

Be apart in this moment of time, which will shape how internal combustion engines are going to be built in the 21st century.

To view a video about the product/technology visit

RELATED VIDEO

NGK Spark Plug Co., Ltd. (日本特殊陶業株式会社, Nippon Tokusyu Tōgyō Kabushiki-gaisha) (TYO: 5334) is a Public Company established in 1936 and based in Nagoya, Japan. NGK is involved in the manufacture and sale of spark plugs and related products for internal-combustion...

NGK Spark Plug Co., Ltd. (日本特殊陶業株式会社, Nippon Tokusyu Tōgyō Kabushiki-gaisha) (TYO: 5334) is a Public Company established in 1936 and based in Nagoya, Japan. NGK is involved in the manufacture and sale of spark plugs and related products for internal-combustion...

An oxygen sensor, or lambda sensor, is an electronic device that measures the proportion of oxygen (O2) in the gas or liquid being analyzed.

An oxygen sensor, or lambda sensor, is an electronic device that measures the proportion of oxygen (O2) in the gas or liquid being analyzed.