In general, energy conversion efficiency is the ratio between the useful output of a device and the input, in energy terms. For thermal efficiency, the input, , to the device is heat, or the heat-content of a fuel that is consumed. The desired output is mechanical work, , or heat, , or possibly both. Because the input heat normally has a real financial cost, a memorable, generic definition of thermal efficiency is

When expressed as a percentage, the thermal efficiency must be between 0% and 100%. Efficiency is typically less than 100% because there are inefficiencies such as friction and heat loss that convert the energy into alternative forms. For example, a typical gasoline automobile engine operates at around 25% efficiency, and a large coal-fueled electrical generating plant peaks at about 46%. The largest diesel engine in the world peaks at 51.7%. In a combined cycle plant, thermal efficiencies are approaching 60%. Such a real-world value may be used as a figure of merit for the device.

For engines where a fuel is burned there are two types of thermal efficiency: indicated thermal efficiency and brake thermal efficiency. This efficiency is only appropriate when comparing similar types or similar devices.

For other systems the specifics of the calculations of efficiency vary but the non dimensional input is still the same. Efficiency = Output energy / input energy

Heat engines[edit]

Heat engines transform thermal energy, or heat, Qin into mechanical energy, or work, Wout. They cannot do this task perfectly, so some of the input heat energy is not converted into work, but is dissipated as waste heat Qout into the environment

The thermal efficiency of a heat engine is the percentage of heat energy that is transformed into work. Thermal efficiency is defined as

The efficiency of even the best heat engines is low; usually below 50% and often far below. So the energy lost to the environment by heat engines is a major waste of energy resources. Since a large fraction of the fuels produced worldwide go to powering heat engines, perhaps up to half of the useful energy produced worldwide is wasted in engine inefficiency, although modern cogeneration, combined cycle and energy recycling schemes are beginning to use this heat for other purposes. This inefficiency can be attributed to three causes. There is an overall theoretical limit to the efficiency of any heat engine due to temperature, called the Carnot efficiency. Second, specific types of engines have lower limits on their efficiency due to the inherent irreversibility of the engine cycle they use. Thirdly, the nonideal behavior of real engines, such as mechanical friction and losses in the combustion process causes further efficiency losses.

Carnot efficiency[edit]

The second law of thermodynamics puts a fundamental limit on the thermal efficiency of all heat engines. Even an ideal, frictionless engine can't convert anywhere near 100% of its input heat into work. The limiting factors are the temperature at which the heat enters the engine, , and the temperature of the environment into which the engine exhausts its waste heat, , measured in an absolute scale, such as the Kelvin or Rankine scale. From Carnot's theorem, for any engine working between these two temperatures:

This limiting value is called the Carnot cycle efficiency because it is the efficiency of an unattainable, ideal, reversible engine cycle called the Carnot cycle. No device converting heat into mechanical energy, regardless of its construction, can exceed this efficiency.

Examples of are the temperature of hot steam entering the turbine of a steam power plant, or the temperature at which the fuel burns in an internal combustion engine. is usually the ambient temperature where the engine is located, or the temperature of a lake or river that waste heat is discharged into. For example, if an automobile engine burns gasoline at a temperature of and the ambient temperature is , then its maximum possible efficiency is:

It can be seen that since is fixed by the environment, the only way for a designer to increase the Carnot efficiency of an engine is to increase , the temperature at which the heat is added to the engine. The efficiency of ordinary heat engines also generally increases with operating temperature, and advanced structural materials that allow engines to operate at higher temperatures is an active area of research.

Due to the other causes detailed below, practical engines have efficiencies far below the Carnot limit. For example, the average automobile engine is less than 35% efficient.

Carnot's theorem applies to thermodynamic cycles, where thermal energy is converted to mechanical work. Devices that convert a fuel's chemical energy directly into electrical work, such as fuel cells, can exceed the Carnot efficiency.

Engine cycle efficiency[edit]

The Carnot cycle is reversible and thus represents the upper limit on efficiency of an engine cycle. Practical engine cycles are irreversible and thus have inherently lower efficiency than the Carnot efficiency when operated between the same temperatures and . One of the factors determining efficiency is how heat is added to the working fluid in the cycle, and how it is removed. The Carnot cycle achieves maximum efficiency because all the heat is added to the working fluid at the maximum temperature , and removed at the minimum temperature . In contrast, in an internal combustion engine, the temperature of the fuel-air mixture in the cylinder is nowhere near its peak temperature as the fuel starts to burn, and only reaches the peak temperature as all the fuel is consumed, so the average temperature at which heat is added is lower, reducing efficiency.

An important parameter in the efficiency of combustion engines is the specific heat ratio of the air-fuel mixture, . This varies somewhat with the fuel, but is generally close to the air value of 1.4. This standard value is usually used in the engine cycle equations below, and when this approximation is made the cycle is called an air-standard cycle.

Thus, the efficiency increases with the compression ratio. However the compression ratio of Otto cycle engines is limited by the need to prevent the uncontrolled combustion known as knocking. Modern engines have compression ratios in the range 8 to 11, resulting in ideal cycle efficiencies of 56% to 61%.- Diesel cycle: trucks and trains In the Diesel cycle used in diesel truck and train engines, the fuel is ignited by compression in the cylinder. The efficiency of the Diesel cycle is dependent on and like the Otto cycle, and also by the cutoff ratio, rc, which is the ratio of the cylinder volume at the beginning and end of the combustion process:

- Rankine cycle: steam power plants The Rankine cycle is the cycle used in steam turbine power plants. The overwhelming majority of the world's electric power is produced with this cycle. Since the cycle's working fluid, water, changes from liquid to vapor and back during the cycle, their efficiencies depend on the thermodynamic properties of water. The thermal efficiency of modern steam turbine plants with reheat cycles can reach 47%, and in combined cycle plants, in which a steam turbine is powered by exhaust heat from a gas turbine, it can approach 60%.

- Brayton cycle: gas turbines and jet engines The Brayton cycle is the cycle used in gas turbines and jet engines. It consists of a compressor that increases pressure of the incoming air, then fuel is continuously added to the flow and burned, and the hot exhaust gasses are expanded in a turbine. The efficiency depends largely on the ratio of the pressure inside the combustion chamber p2 to the pressure outside p1

RELATED VIDEO

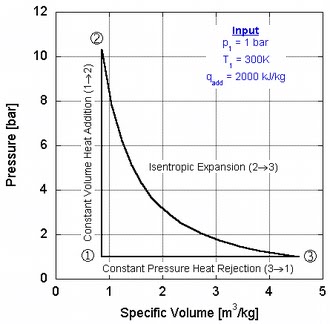

The Lenoir cycle is an idealized thermodynamic cycle often used to model a pulse jet engine. It is based on the operation of an engine patented by Jean Joseph Etienne Lenoir in 1860. This engine is often thought of as the first commercially produced internal...

The Lenoir cycle is an idealized thermodynamic cycle often used to model a pulse jet engine. It is based on the operation of an engine patented by Jean Joseph Etienne Lenoir in 1860. This engine is often thought of as the first commercially produced internal...

A steam car is a light car (automobile) powered by a steam engine.

A steam car is a light car (automobile) powered by a steam engine.